Machine Learning is the future of supply chain planning and execution systems, and the future is now! I say this with utmost confidence, after having gone through various articles and case studies based on different industries ranging from automotive to textile. The buzz is on making supply chains more sustainable, and end-to-end optimization of supply chains is only possible if all the different entities within the industry working synchronously with overlapping synergies. This is true in most cases with major companies mostly following a decentralized way of working, but still, some challenges are pertinent in the day-to-day. With the focus being on the automotive sector in the short article, I would say that major players in the industry are trying to optimize customer value with adaptable and innovative supply chain solutions. Identifying and implementing Machine Learning (ML) algorithms on real data received by connected vehicles may result in identifying effective engine driving cycles and opens up possibilities to leverage this data for future predictive analytics use cases.

The complexities involved within the automotive sector are numerous because companies have to deal with various networks – from dealers to suppliers, logistical simulation models, and conjugating demands. The convergence of cloud computing, the Internet of Things (IoT), and other devices effectively make up big data and predictive analysis. The underlying theme behind inventory management, demand and supply planning, and end-to-end optimization lies in how data management is prioritized. Industrial product segments within the automotive sector have different focuses based on different product archetypes and the type of field tests being conducted on the same. Right now, the industrial focus is moving at a rapid pace towards autonomous cars, but it all started with trucks and buses which helped in transporting goods across highways. Setting up a database structure from raw data is not an easy task, and using Azure SQL database or AWS database, not only can we simplify this process but also use it for agile ways of working but also follow through with agile planning, work item tracking, data visualization, reporting, and so on. Fostering a data-driven culture with overlapping interfaces is the key to collaborative initiatives and practices relating to sustainable supply chains.

Cloud Computing in Automotive Industry

In the autonomous vehicles space, Microsoft has been working towards enabling their partners on their cloud computing platform, ‘Microsoft Azure’ which is available in 18 categories with over 200 services. Microsoft has also been working on their ‘Microsoft for startups’ program which is aimed towards digital transformation particularly catering to autonomous start-up companies, helping in their solution development and also, providing these start-ups with free access to Microsoft’s technologies, and go-to-market resources. Using Microsoft Azure, autonomous vehicle engineers around the globe can build and safely deploy autonomous vehicles at scale. In terms of cost-effectiveness, improving safety, accessibility, and other keywords associated with autonomous vehicles, Azure is essentially providing a platform where companies can do it in a better and faster way while being connected to the cloud. I used the example of Microsoft Azure to make it synchronous to read, but their major competitor, Amazon Web Services (AWS) also provides cloud-based services within the automotive sector for autonomous and connected vehicles.

Not only do the cloud computing software help in creating a personalization-based service for the automation sector, within the factory setting, but cloud computing is also used at a massive scale for inventory management, re-filling of parts and tools, and change tracking capabilities. For example, based on the source you are synced with you could integrate virtual machine management capabilities to enable inventory management, change tracking, and so on. Getting a unified view across the portal is important since that is the key to have management capabilities at scale using Azure.

Above and Beyond

A company’s supply chain innovativeness, today, is based on big data predictive analysis with a focus on cloud-based infrastructure. Predictive analysis using a high-level general-purpose programming language such as Python is not new and using Azure, you can create a pipeline to automatically build and test Python scripts. Using ‘Azure Pipelines’, continuous integration, and delivery for consistent test build is possible and within the automotive sector, developing intelligent systems based on Machine Learning (ML) and Artificial Intelligence (AI) is an important factor to consider.

With cloud-computing services such as Azure, data visualization becomes very straightforward and easy. Since the cloud is also connected to the Database Management System (DBS) repository, you can make use of real-time systems to extract, embed, and transform your data sources to fit different requirements and processes. Innovation is the heart of everything that happens within any industry, and the automotive industry is no exception. The synergies between different industries coming together to understand and improve services within their frontiers are amazing and the success of the supply chains to be sustainable and work on time is owed to the fact of all systems coming together to work. Increased transparency in the supply chain is required for customer demand fluctuation to manage expenses and ramp-up production concerning vehicle tracking solutions. Leveraging Artificial Intelligence to get better insights on customer demand using the Azure AI platform helps in real-time demand forecasting and provides visibility gaps in the planning to the execution stage.

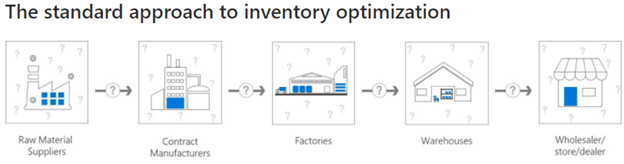

Unifying communication between cross-functional teams is made easier and the compliance of quality is also maintained while product documentation and policy updates are made on the Azure platform seamlessly. Multi-echelon inventory optimization involves modeling multiple stages of the system to accurately predict cycle stock and to accommodate forecasted demand.

Multi-echelon Inventory Optimization (MEIO) permits OEMs to intensify demand modeling and balance inventories with ease covering the network of supply chain processes with existing data and improvising and learning using machine learning capabilities – all using the cloud computing software (Microsoft Azure). MEIO allows increased visibility and traceability across all echelons of the supply chain empowering centralized demand planning, streamlined operations, and cost-reductions owing to stock optimization between the upstream and downstream distribution points.

ToolsGroup MEIO, built on Microsoft Azure boosts inventory planning and accelerates growth via an automated supply chain intelligence capability. By leveraging the demand and inventory modeling technology with existing order data, stock-outs are immensely reduced and inventory turns are improved. Across multiple distribution and manufacturing echelons, supply chains are optimized effectively.

This easy-to-use and implement solution dramatically reduces computational workload, empowering employees to focus on higher-level inputs impacting day-to-day operations and adjust where needed, enables employees and partners to manage demand via a collaboration hub accessible on any device, anytime, leverages intuitive visualizations and dashboards to report core analytics and manage exceptions. (“Advantages of Multi-Echelon Inventory Optimization – Microsoft Industry Blogs” 2018)

References

“Advantages of Multi-Echelon Inventory Optimization – Microsoft Industry Blogs.” 2018. July 17, 2018. https://cloudblogs.microsoft.com/industry-blog/manufacturing/2018/07/17/advantages-of-multi-echelon-inventory-optimization/.