Introduction

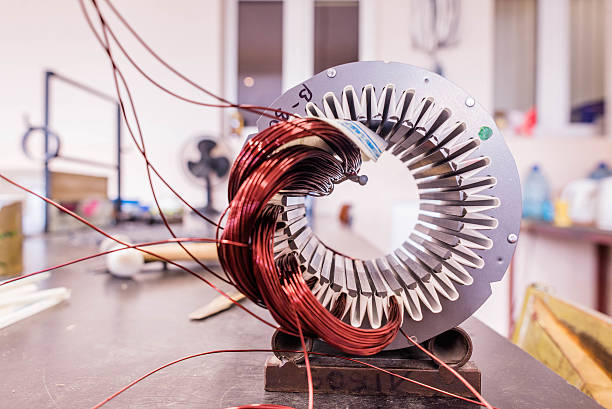

As the world becomes more conscious of environmental issues, sustainability is increasingly emphasized in various industries. One such industry is the electrical equipment sector, where motors and generators play a crucial role. However, these machines eventually reach the end of their useful life and must be disposed of properly to minimize their environmental impact. This is where the concept of “closing the loop” comes into play.

Closing the loop refers to the process of recycling and reusing materials and components from old machines to create new ones. This approach reduces waste and minimizes the need for new raw materials. According to ABB’s data, up to 98% of materials can be preserved, recycled, and recovered from used machines. This process benefits the environment and has socio-economic advantages, such as reducing the cost of manufacturing new equipment and building brand credibility. As part of its efforts to “close the loop,” ABB recently partnered with Stena Recycling to offer customers the opportunity to recycle old machines.

Recognizing the importance of sustainability, ABB, a market leader in the electrical equipment industry, organized a student competition to encourage innovation in improving sustainability within the motors industry.

I am proud to say that my friend Jithin Jomy and I won second prize in this competition, highlighting the growing interest in this topic among students and the wider public.

One significant challenge faced by the industry is the end-of-life of motors and generators. They contain valuable materials, including copper, aluminum, steel, and rare earth metals, which are expensive and have limited availability. Recovering and recycling these materials from old equipment efficiently is a challenge.

Furthermore, there is a market gap that still needs to be addressed effectively. The accountability and traceability of recycled machines must be improved to provide concrete data on the percentage of machines being recycled. This makes it harder for ABB or any company to claim with certainty about the percentage of machines being recycled and to assure customers of the potential benefits. As a result, companies find it harder to market their efforts towards improving sustainability to customers and suppliers.

Our Solution

Our proposal is for ABB to create a system that authorizes and grants “certified ABB recycle centers” badges to recycling centers located in different parts of the world. This system would be similar to the certified car servicing centers in India. By doing so, our solution helps ABB set up local partnerships with recycling centers. ABB can then ask its customers to return and recycle their used machines at these certified recycling centers. The complete data and information about these centers will be available on ABB’s website. Additionally, ABB will provide a detailed handbook and guidelines that the certified recycling centers must abide by to maintain their certified badge from ABB. This will ensure:

- Recycling centers have a guaranteed source of income through ABB channels.

- ABB can get accurate and complete data on the total machines being recycled, which can later be used for publicizing new products and retaining old customers.

- The guidelines set by ABB will always ensure that customers receive a fair price for their used machines.

- The vast network of recycling centers will help ABB’s suppliers procure recovered materials from motors and generators in a more efficient and cost-effective manner.

This creates a symbiotic relationship and synergy between ABB, suppliers, recycling centers, and customers, resulting in a win-win situation for all stakeholders involved.

Conclusion

In conclusion, closing the loop at the end of the life of motors and generators is an important concept that can significantly reduce the environmental impact of the electrical equipment industry. This requires collaboration between various stakeholders, including manufacturers, recyclers, policymakers, and customers. By implementing effective recycling and reuse practices, we can create a sustainable future for the electrical equipment industry and beyond.

We propose an interesting solution to tackle the problem of ensuring accountability and building customer trust in machine recycling. Our solution also offers potential benefits, which are listed below.