Indrajith Sharma (Co-founder & CTO – VertiKal Farms)

Problem statement

For over 3years living in Germany and traveling across cities with friends and family and observed few facts about people living. Almost all the vegetables sold in Germany are either frozen, canned, or sold in packets with fixed expiration dates of 2-3days. Also, among the places visited, the author saw that there were more than the normal amount of fresh flower selling shops in any city. On a visit to any grocery store across the country, one would see small earthen pots with plants in their germination stage. Also, staying in different student dormitories, where the author experienced day-in and day-out, whether summer or winter people brought new plants and placed them inside their room, common areas, or balconies. And while talking to students and young professionals from different backgrounds, the enthusiasm people had over growing flowers or everyday use plants at home to reduce the frequency of visits to convenience stores. The joy of watering the plants every day and decorating their homes with color brought them immense pleasure and acted as a moment of pride and style.

What problems do your customers currently have?

- Insufficient fresh food production in Germany: There is a total of ~21% less food production in Germany when compared to the total population. Canned, pre-packed frozen and preserved food supplies are not an answer to alternatives of fresh produce.

- Expensive alternate options: The cumulative cost incurred while growing kitchen plants in terms of resources, cost of failure, and time – converge to be an expensive investment.

- Lack of knowledge: To cater to the need for fresh food, indoor gardening products, and community gardens are used as an alternative solution. However, 35% of the interviewees claimed that they want to grow their own food, but lack of knowledge, long working hours, and complicated growing procedures, are driving them towards alternate food supplies. (DORTE VERNER, 2017)

- Inefficient alternatives: Our survey analysis has shown that even though frozen or refrigerated food does not lose its nutritional value, people prefer fresh vegetables, as these alternatives are soggy and wet, and they cannot act as a long-term solution.

- Lack of efficient community gardens: Experienced plant breeders lease space from community gardens and grow their own food. However, due to limited space, new users must wait for almost a year to lease a community land space at the rate average price of €200 per month, with an additional cost of resources. Even though the cumulative costs are substantially high, people lease community gardens to grow their own choice of food, at their convenience.

- Cold climatic conditions: In addition to the weak alternatives, the climatic conditions in Germany are not in favor of year-round food production. 20% of the consumers that have an active herb garden claim that they are unable to maintain plant health during the cold climatic conditions, their plants usually dry up even after constant care.

Description of solution

Unique selling point and clear understanding of the solution

Product description:

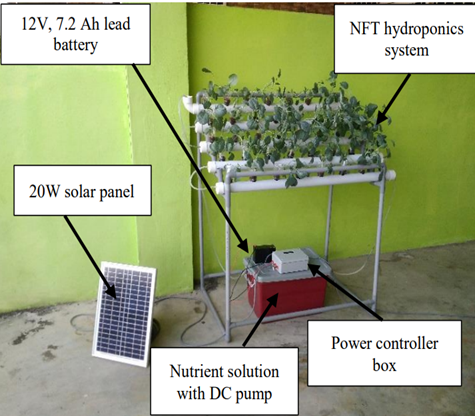

– One of the common issues among most people in Berlin is the lack of simple, low-maintenance, and cost-efficient home gardens. Inline, I have developed a semi-automated DIY (Do-It-Yourself) portable urban farming home-kit.

- The kit could be set up anywhere in the house, as the user sees fit, any indoor room, balcony, or kitchen would be perfectly efficient. As the product is a vertical erect, space would not be an issue. Semi-Automated, so people will not need any prior knowledge on gardening,

- Required light would be provided via LED grow lights. These would act as an alternate source for sunlight, letting user grow food all year round, even during cold climatic conditions, at low costs,

- This system would provide for a family of 2 or 4 depending on the size of the home-kit ordered. A single user could use a smaller version of the home-kit, to provide for themselves.

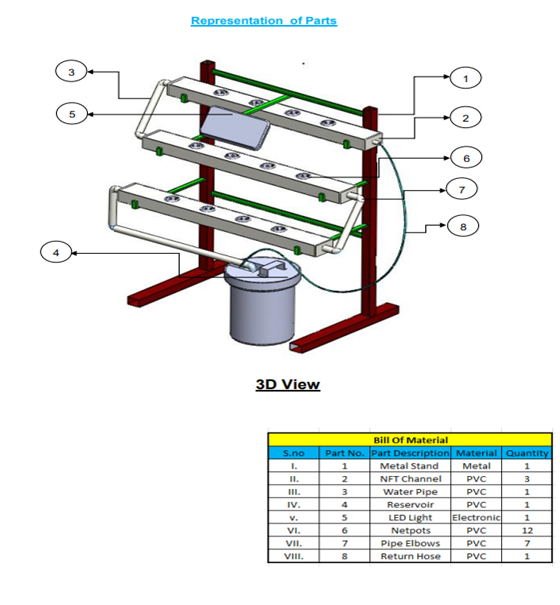

- The system would consist of:

- Seed tray + seeds • Assembly tools

- Home-kit frame • Manual on how to set up the home-kit

- Grow medium • A mobile application to guide user on

- VERTIKAL – Nutrient solution how & when to add nutrient mix

- Measuring cup • LED grow lights

Innovation in the system

- Product Innovation: Hydroponic systems have been part of modern-day AgriTech for over80years now, still we have not been able to use the technology to its full potential.

- VERTIKAL has designed the frame, to increase the crop production in same confined space with minimal water consumption, adding to the efficacy of the system.

- To price the product at affordable costs, the whole system has been designed based on industry component standards, making the home-kit a much cheaper & simpler version of home gardens.

- Low water consumption, the home-kit uses 90% less water than traditional farming techniques

- A result of a survey was sent across Berlin to people from different age groups in the month of February 2021 and 340 responses were recorded. The survey included multiple questions such as segregation as per population statistics, the relative size of community gardens in their vicinity, general food habits, grocery shopping, problems faced when one starts to grow their own leafy vegetables, water depletion effects, etc. A sample target of 340 responses in which 286 responses were sample section was taken into consideration.

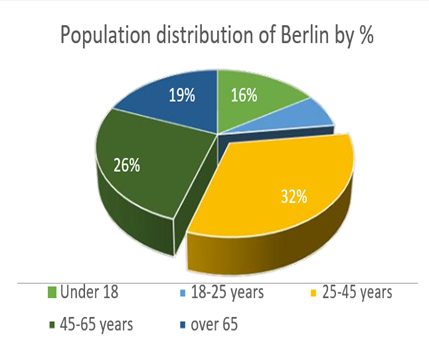

- The target audience is 32% of total population i.e. 32% of 3.7 million = ~1.2 million people.

Adaption of renewable resources

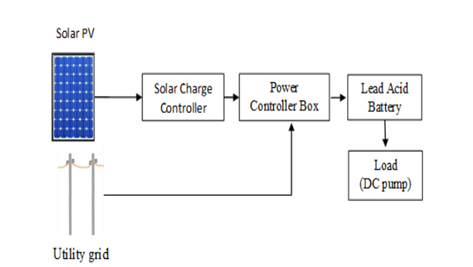

The researcher has also been able to identify several parameters that will necessarily have an impact on sustainability. Solar energy was regarded as the best alternative to reduce the loads and costs of household electricity (Hussin, Amin, Safar, Majid, & Nasir, 2018). The total solar PV capacity in Germany is increasing every year and hence it makes sense to implement a hybrid system to draw energy from panels and reduce the loads on the utility grid. The hydroponic system uses an AC water pump which directly draws electricity from the grid, however by adapting the DC water pump the green energy consumption can be made more sustainable. Ideally, a solar panel ranging from 15 to 20W with a solar charge controller and a combination of 12V. 7Ah lead-acid battery is widely available in the market can be used, however, a wide recursive study is needed.

A PLC can be customized with variable inputs which monitors the output based upon predefined parameters.

Different DC applications can be considered which may result in reduction in power consumption around 40%.

Even though implementing a polycrystalline solar panel would increase the initial costs along with the hydroponic system, the energy stored can be used during adverse weather conditions thus making the whole potable system completely green which is ideal for the environment.

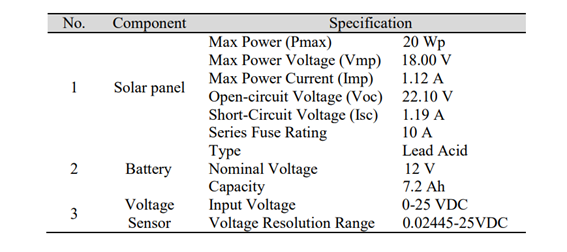

Component’s specifications

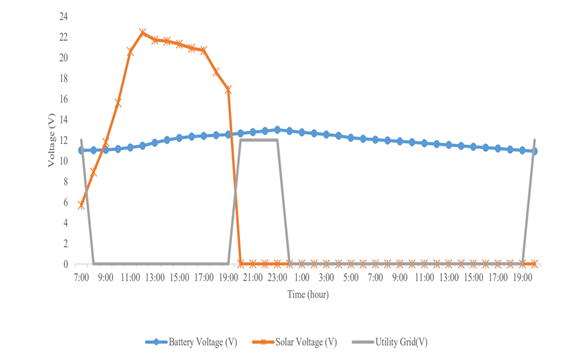

The battery charging using hybrid power sources also has been tested. The results in the graph below are presenting the capability of performing battery charging for 1 complete cycle when the solar PV and utility grid are available. Observation shows that the battery is connected to the load and the hybrid power sources are connected to the charge lead-acid battery. The selection of the power source is depending on the availability of solar and grid. The battery starts charging at 𝑉𝑀𝐼𝑁 =11V. In this case, the solar is available from 8 am to 7 pm. The battery is charging using the utility grid before 8 am. Then, the solar PV starts charging the battery using solar at 8 am because the solar voltage is more than 12V. The battery voltage increments are about 1.54V during the daytime. After 7 pm, the microcontroller switches the relay to continue the charging process until the battery is fully charged at 3.08V. The utility grid is used approximately about 4.5 hours for another 0.54V voltage increments. When the battery is fully charged, the charging process will stop. The battery will discharge until 11.0 V before the charging process take place

Product Demo

Business Model

Market Potential

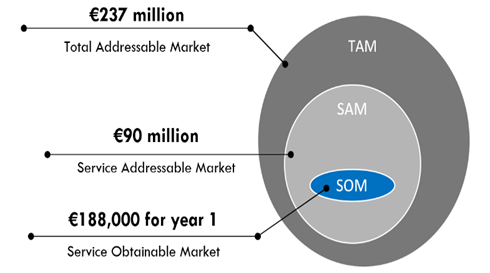

Estimation of Market Size, Berlin:

- In a 2018 market research conducted by Georgian Farmer Association (GFA), the average per capita expenditure on food & beverages in Germany stands at €167/month.

- Our initial target market is Berlin, based on general population age-segmentation we have received 75% of responses from people between the 25-45-year age group

- Assumptions:

- 10% of the monthly expenses to be spent on fresh vegetables & fruits

- 40% of the population have home-made salads, at least 4-5meals/week

- 13% conversion rate with respect to standard marketing conversion KPIs

| Average monthly expenses on vegetables in Germany | € | 167 |

| Assuming, 10% spent on Vegetables | € | 16.7 |

| Yearly expenses, per person | € | 200.40 |

| Total population of Berlin, million people | 3.7 | |

| Target audience, 32% are in 25-45 age group, million people | 1.2 | |

| Total Addressable Market (TAM), € million | € | 237.3 |

| 40% of the target audience, thousand people | 473.6 | |

| Product cost, € | € | 190 |

| Service Addressable Market SAM), € million | € | 90 |

| Number of people hired @ 30calls/day | 3 | |

| Calls per year | 19800 | |

| Assuming, conversion per person | 5% | |

| Total home-kits sold | 990 | |

| Product cost, € | € | 190 |

| Service obtainable Market (SOM), € thousand | € | 188 |

To acquire Service Obtainable Market (SOM), a recruitment strategy will be followed, 3 people:

Conservation of Land, Energy and Water usage by reducing environmental impact

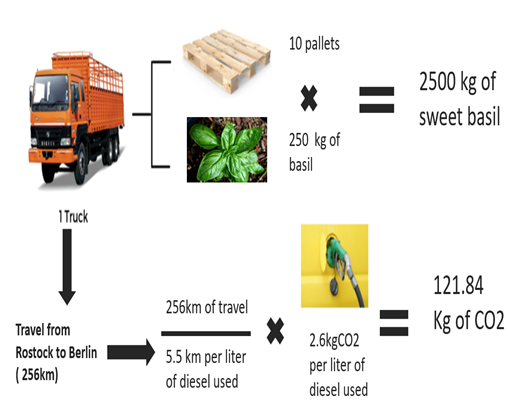

A fully loaded diesel truck traveling for 256kms burns around 2.6kg of CO2 per km. The production of basil in traditional farming in Rostock, Germany is transported all over, carrying approximately 10 pallets with each pallet containing 250kg of sweet basil. The packaging, wastage was considered as 20%, so a total of 90grams of CO2 is emitted per plant was calculated. However, this amount is small for basil grown in the open field. But when exported to whole Germany the carbon footprint is relatively larger per Kg of basil produced.

In comparison with HPS, the transport costs are negligible as the portable system is one time shipped from different warehouses located in Berlin. The average distance traveled to reach customers is 10km. The nutrient solution Part-A and B is 250ml. For one harvest it was found out that 130ml of Part-A and 130ml of Part-B, NS was required. So, the transportation of nutrient solutions would be four times a year. CO2 emissions were calculated for both scenarios and results to prove that with the adoption of HPS a 54.84% reduction in carbon emissions.

121.845 Kg of CO2 combusted ÷ 80% × 2500 Kg of basil = 90.8 grams of CO2 combusted for each basil plant from transportation.

Conclusion

This research can be concluded that, for the first time, a design and implementation of a portable hydroponic system was conducted. The system was designed based on industry standards with optimal use of resources to solve the existing problem of water scarcity and time interval of food production and consumption. Though over a view on the pricing of these portable systems would provide an understanding of the budget required to install. The portable system is made accessible for people with minimal knowledge of urban farming techniques. It was necessary to determine the technical and economical efficiencies by conducting a comparative analysis of their performance cycles.

The methodology undertaken in the research included surveys and interviews to design a portable system. For the primary analysis, data like water usage, energy consumption, and CO2 emissions were recorded from the prototype. A one-time analysis was considered for traditional methods. The data collected for secondary analysis was a result of average from works of literature cited. In comparison with traditional or conventional farming methods, where huge lands are irrigated in peri-urban areas. The food produced here is transported to urban cities which causes emissions of toxic gases from automobile industries. The nutrient solution used was particularly developed for leafy greens, however providing a way to cultivate more crops in soilless media. A sensitivity analysis was conducted to understand the environmental impact of categories like climate change, water, and fossil depletion, and agricultural land output. Due to urbanization, the world is short of fresh water and food. The differences in energy consumption were identified in both production methods.

The emissions were reduced by 54% and water usage was 33% less by the adaption of this designed system. This research, therefore, proves strategies to be utilized for medium and large-scale productions. The analysis undertaken will add value to future rising vertical farm productions even in harsh weather conditions with economically profitable consumer preferences.

References

DORTE VERNER, S. V.-L. (2017). Unleashing Climate-Smart & Water-Saving Agriculture Technologies In Mena. MIDDLE EAST AND NORTH AFRICA. Washington, DC: e International Bank for Reconstruction and Development/ The World bank. Retrieved MARCH 13, 2021`, from http://documents1.worldbank.org/curated/en/103361524057787356/pdf/RWSAT-AUS.pdf

How to Feed the World in 2050. (n.d.). Retrieved 2 4, 2021, from Food and Agriculture Organization: http://www.fao.org/fileadmin/templates/wsfs/docs/expert_paper/How_to_Feed_the_World_in_2050.pdf

Hussin, N., Amin, N., Safar, M., Majid, M. S., & Nasir, N. F. (2018). Smart Hydroponic System with Hybrid Power Source. Journal of Telecommunication, Electronic and Computer Engineering, 10, 35-39. Retrieved 3 31, 2021, from http://journal.utem.edu.my/index.php/jtec/article/view/3988

William MacDougall . (2019/2020). The Food and Beverage Industry in Germany . Germany: Germany Trade and Invest .